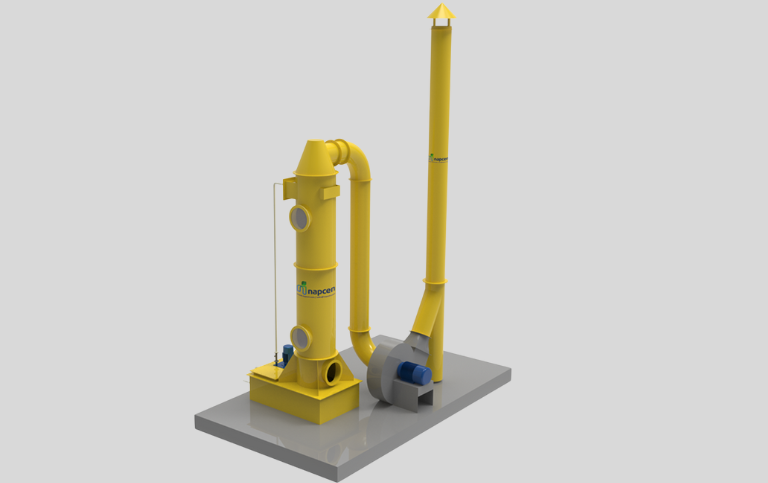

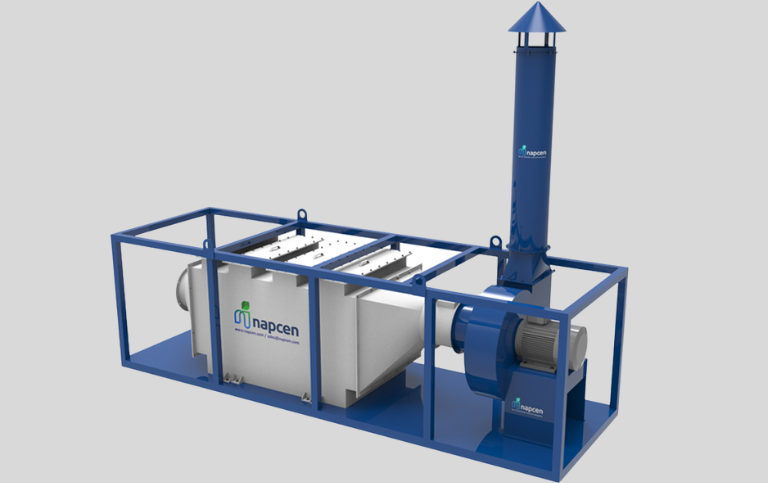

Wet Dust Collector

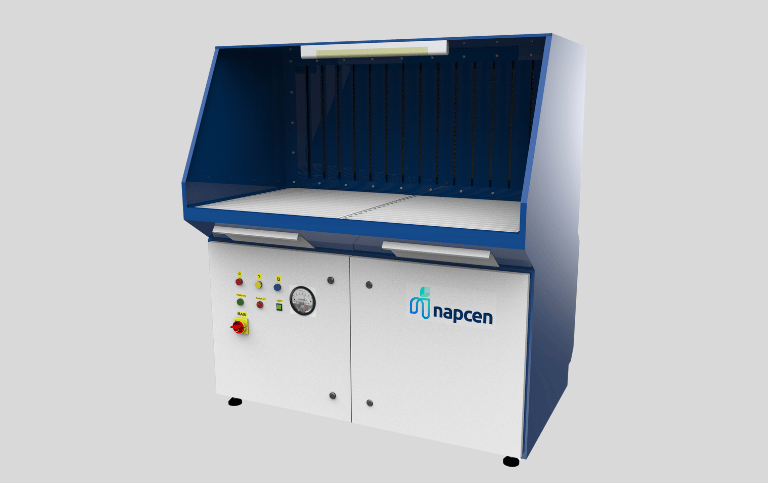

NAPCEN manufactures advanced wet dust collectors designed for hazardous dust and fume extraction applications. These systems utilize wet filtration to capture and remove suspended solid particles from the air, ensuring a cleaner and safer production environment.

Categories:

Wet Dust CollectorNapcen Wet Dust Collectors are specifically engineered to safely capture and contain combustible dust particles using a water-based filtration method, significantly reducing the risk of explosions. Ideal for handling highly explosive reactive dust such as aluminum, titanium, and oil mist the wet dust collector uses a water spray mechanism to effectively separate and neutralize airborne particulates, significantly reducing the risk of fire explosion.

Why Choose Our Wet Dust Collector?

- 99 % collection efficiency for aluminum, magnesium and pharmaceutical dust

- Water-based filtration eliminates explosion risk from combustible dust

- Corrosion-resistant FRP or SS construction for harsh environments

- Low pressure-drop design reduces fan power consumption

- Modular capacities from 1,000 m³/h to 40,000 m³/h—perfect for new builds

- Chemical Manufacturing Units

- Metal Finishing & Electroplating Units

- Pharmaceutical Industries

- Battery Manufacturing Plants

- Paint & Coating Facilities