Pulse Jet Dust Collector

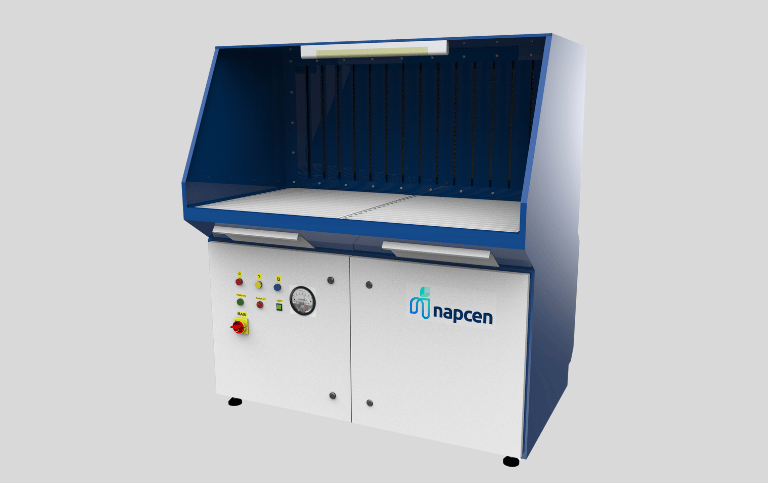

Pulse Jet Dust Collectors are advanced air filtration systems designed with a compressed air cleaning mechanism that can be tailored to suit a wide range of industrial applications, including hazardous environments and sanitary processes. These systems offer high filtration efficiency, making them ideal for product recovery, bin venting, and general dust control. Each unit is custom engineered to meet specific application needs, accommodating factors such as space limitations, process requirements, and operational constraints.

Categories:

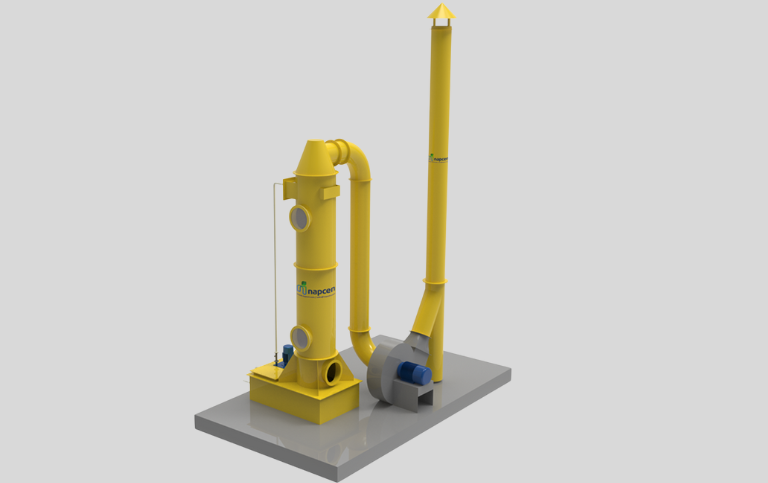

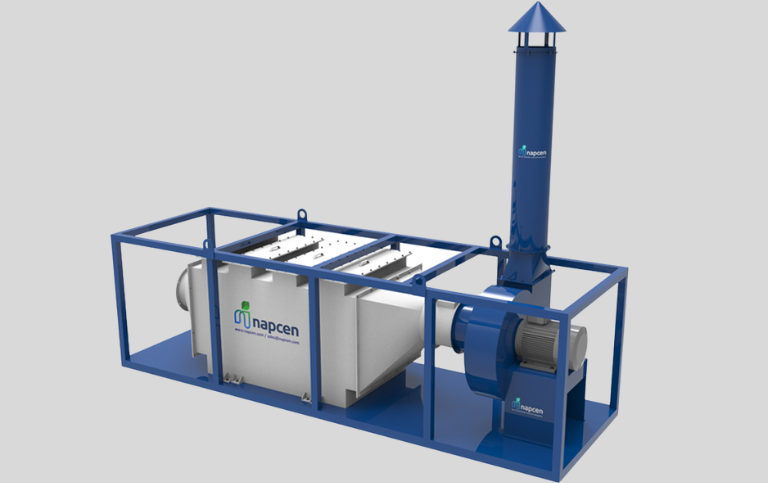

Pulse Jet Dust CollectorsWe provide a pulse jet dust collection system integrated with our grinding plant to prevent dust particles from dispersing into the open air. The system features filter bags and cages housed in a chamber, with pulsing valves and a common air header that periodically clean the filters using compressed air. A rotary airlock valve at the bottom cone discharges collected dust into a silo or drum. A pneumatic vibrator ensures smooth material flow. Ducting and a suction blower are positioned at the top, releasing only clean air into the environment. The system offers easy operation and requires minimal maintenance.

Why Choose Our Pulse Jet Dust Collectors?

- 99.8 % particle collection efficiency for cement, metal and pharmaceutical dust

- Automated pulse-jet cleaning maintains constant pressure drop and long filter life

- Heavy-duty carbon-steel or stainless-steel construction with explosion venting options

- Modular capacities from 2,000 m³/h to 200,000 m³/h for new plants

- Integrated PLC controls for differential-pressure-based pulsing and remote monitoring

- Cement, lime and gypsum plants

- Pharmaceuticals API manufacturing

- Metal foundries and galvanizing lines

- Chemica petrochemical refineries

- Food-processing, spice and dairy facilities