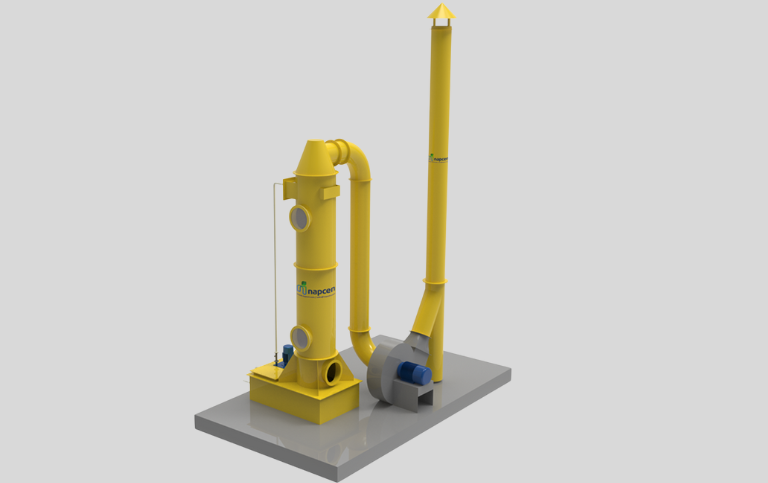

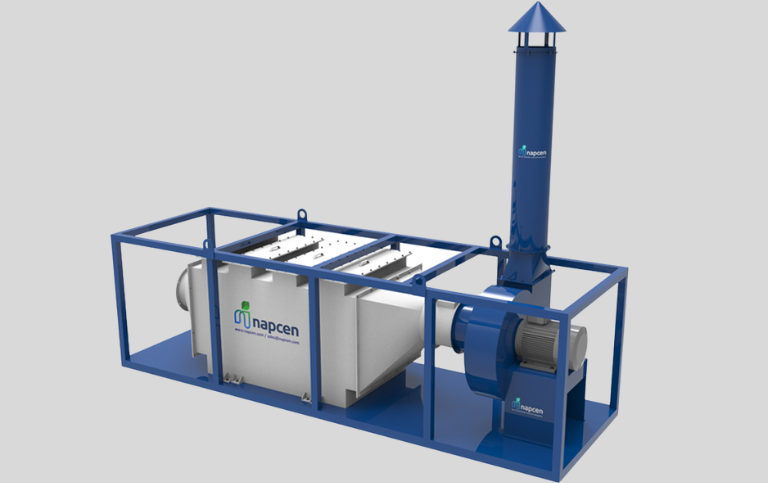

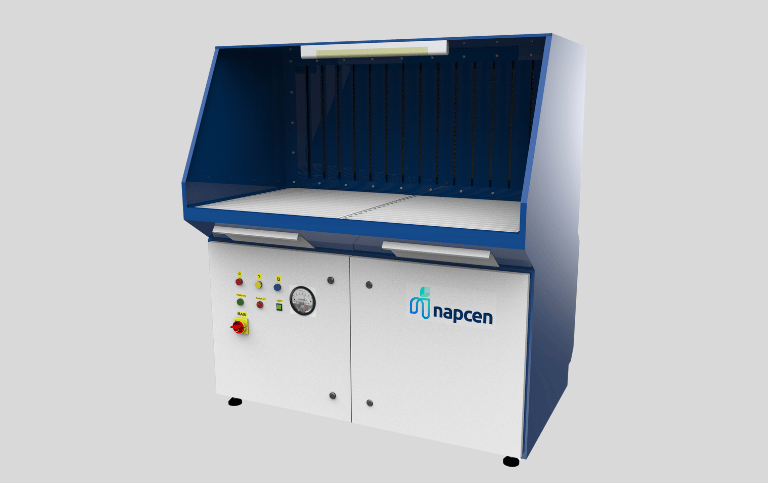

Cyclone Dust Collector

Cyclone dust collectors are commonly used as a first-stage filtration system prefilter to handle heavy dust loads before air reaches a primary collector, such as a baghouse or cartridge system. They are also effective in applications involving product classification or material recovery, where coarse particles can be reclaimed and reintroduced into the process, leaving only fine dust for further filtration. By separating larger particulates from the airstream, cyclones reduce the burden on downstream filters, enhancing their efficiency and extending their service life.

Categories:

Cyclone dust collectorThis cyclone dust collector operates efficient dust removal. Larger and heavier dust particles are separated by the cyclone chamber using centrifugal force as the air spins at high speed. These particles are thrown against the inner wall and fall to the bottom due to gravity, exiting through a discharge outlet. In the second stage, the finer dust that escapes the cyclone is captured in a filter bag, ensuring cleaner air output.

Why Choose Our Cyclone dust collector?

- Up to 95 % collection efficiency for metal chips, sawdust

- Heavy-gauge carbon-steel or SS construction for abrasive environments

- Low maintenance no filter media, simple rotary airlock discharge

- Compact, modular design for airflow from 1,000 m³/h to 100,000 m³/h

- Optional spark arrestor for hot-gas applications

- Chemical Petrochemical Plants

- Pharmaceuticals Cleanrooms

- Foundries Casting Units

- Food Processing & Spices Manufacturing

- Battery Electronics Manufacturing