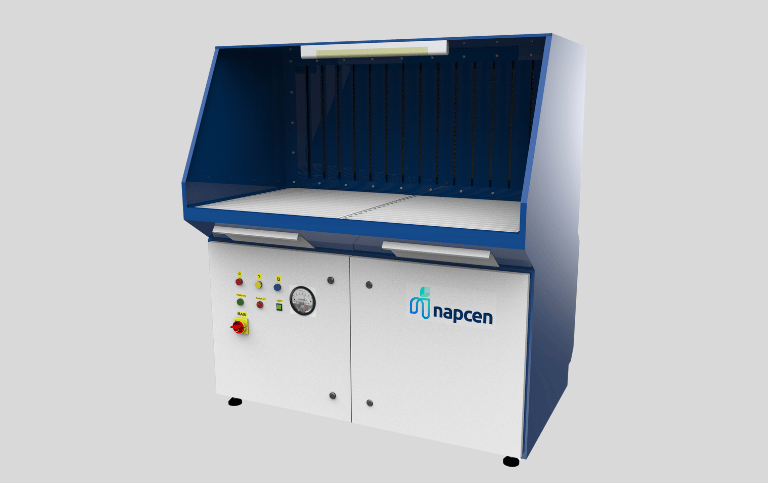

Grinding & Polishing Downdraft Table

A Grinding and Polishing Downdraft Table is a robust air filtration workstation designed to capture dust, fumes, and debris generated during grinding, polishing, and finishing operations.It features a perforated surface connected to a powerful downdraft ventilation system that draws contaminants downward and away from the operator’s breathing zone, improving workplace safety and air quality. Ideal for metalworking, fabrication, and manufacturing environments.

Categories:

Grinding and Polishing Downdraft TableA Grinding and Polishing Downdraft Table is a specialized workstation designed to safely capture and filter dust, fumes, and fine particles generated during grinding, sanding, and polishing processes. Ideal for industrial and fabrication settings, this table integrates a powerful downdraft airflow system that pulls contaminants downward through the work surface. Grinding and Polishing Downdraft Tables support compliance with occupational safety standards and improve overall air quality.

Why Choose Our Grinding and Polishing Downdraft Table?

- 99 % removal efficiency for HCl, SO2, HF and other acid gases

- Robust PP/FRP construction resists corrosion and high temperatures

- Low pressure drop design lowers energy costs and fan size

- Modular capacities from 500 m³/h to 60,000 m³/h for green-field or retrofit projects

- Integrated pumps, recirculation tank and mist eliminator for quick installation

- Chemical petrochemical processing

- Pharmaceutical manufacturing

- Metal pickling and galvanizing

- Fertilizer and pesticide plants

- Battery recycling and acid regeneration