Cartridge Dust Collector

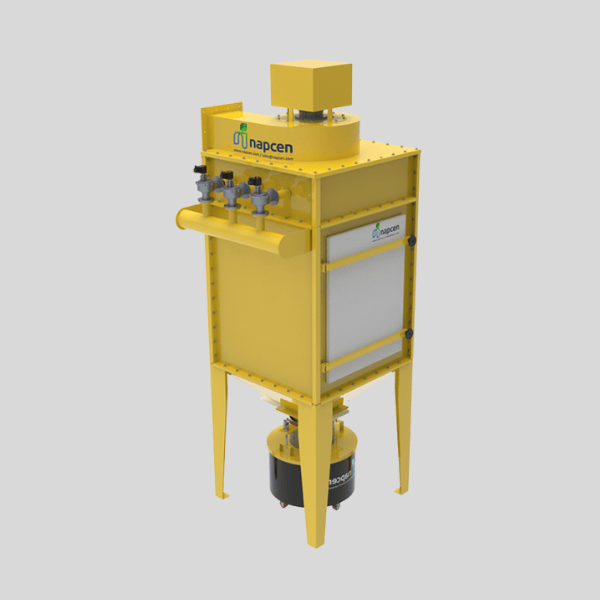

Cartridge dust collector is a widely used filtration system in various industries, known for its efficiency and compact design. Unlike traditional dust collectors that use filter bags, it utilizes cylindrical oval-shaped cartridges lined with pleated nonwoven filter media. These cartridges are open at both ends, but once installed, one end is sealed to direct airflow properly. Dust-laden air enters the collector and passes from the outside to the inside of the cartridge, where particulates are trapped.

Categories:

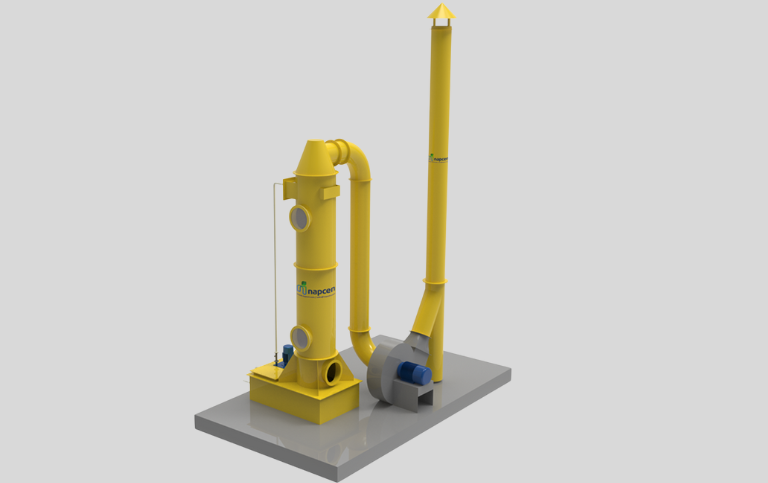

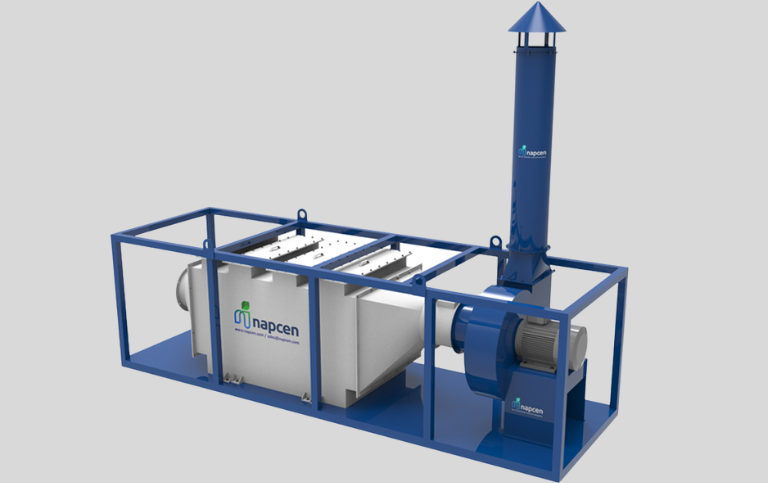

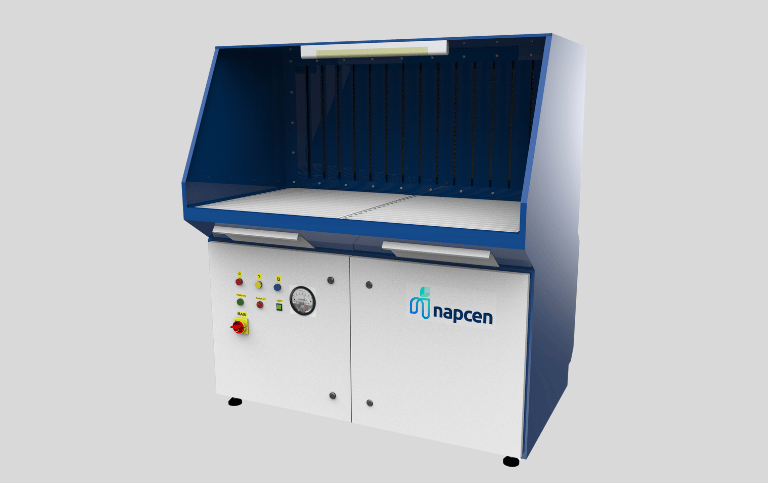

Cartridge Dust CollectorsNapcen manufactures a wide range of dust collectors designed to extract dust generated from grinding machines, shot blasting units, rubber and powder grinding equipment. Our specialized metal dust collection systems are engineered to capture hazardous dust produced during grinding processes. We also offer advanced wet dust collectors that safely handle explosive and reactive metal dust. Featuring a multistage filtration system, our units ensure high filtration efficiency and prevent filter clogging.

Why Choose Our Cartridge Dust Collector?

- 99.9 % filtration efficiency for sub-micron dust

- Vertical cartridge design prevents dust re-entrainment and lengthens filter life

- Compact footprint ideal for CNC shops and confined production areas

- Pulse-jet cleaning maintains low pressure drop and stable airflow

- Modular capacities from 1,000 m³/h to 30,000 m³/h

- Chemical Manufacturing Units

- Pharmaceutical Industries

- Battery Manufacturing Plants

- Metal Finishing and Electroplating Units

- Effluent and Sewage Treatment Plants