Laser Fume Extractor

Laser Fume Extractors are specialized air filtration systems and remove harmful fumes, smoke, and particulate matter generated during laser cutting, engraving, marking processes. These extractors use high-efficiency filters, activated carbon, to trap fine particles and neutralize toxic gases, ensuring clean air is returned to the workspace. They offer reliable protection against airborne contaminants produced by laser based applications.

Categories:

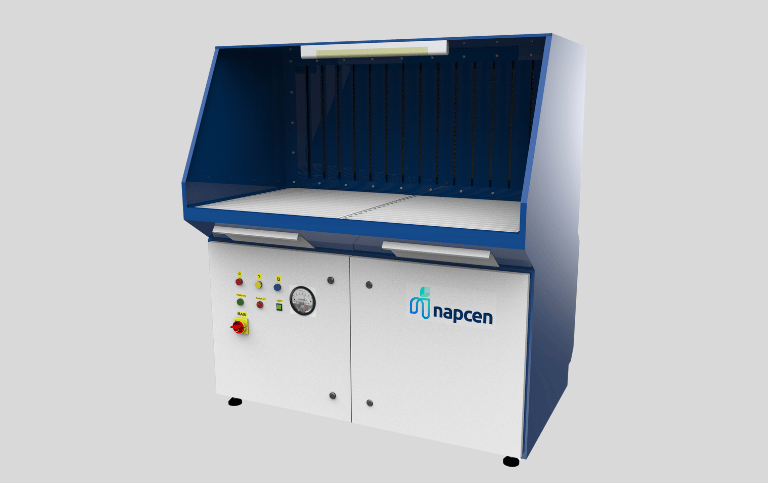

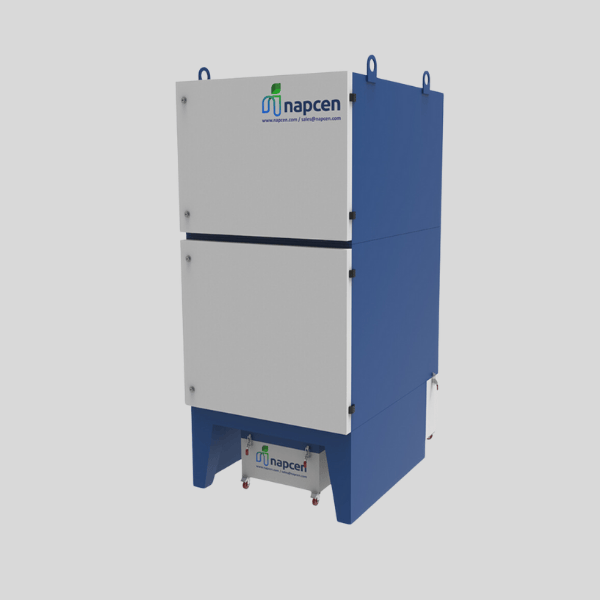

Laser fume extractorNapcen laser cutting fume extractor is designed to effectively manage fumes generated in small scale or low emission operations. The system features a two-stage filtration process, including a pre filter and a cartridge filter, which efficiently captures fine dust and fume particles. Ideal for various laser processing applications, Napcen’s fume and dust extraction system ensures clean air and regulatory compliance in industrial settings.

Why Choose Our laser fume extractor?

- 99.9 % filtration efficiency for PM 2.5 particles and nano-sized laser smoke

- Multi-stage HEPA + activated-carbon filtering for odour and VOC control

- Low pressure-drop design extends filter life and cuts fan power costs

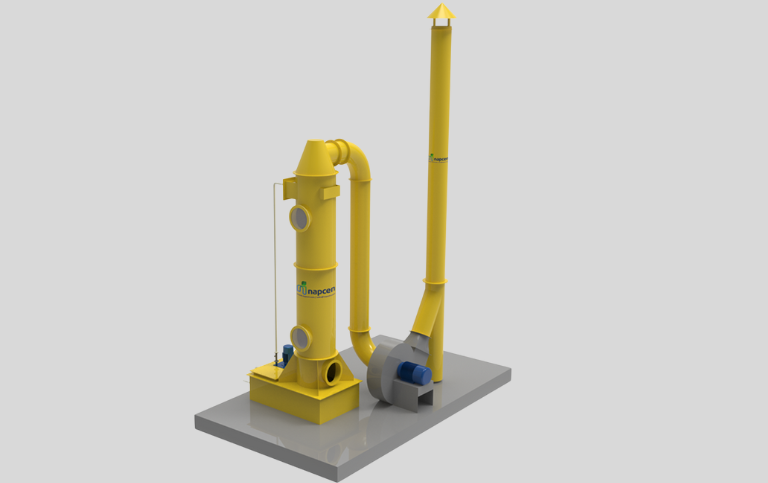

- Corrosion-resistant FRP/PP wet scrubber body for long service life

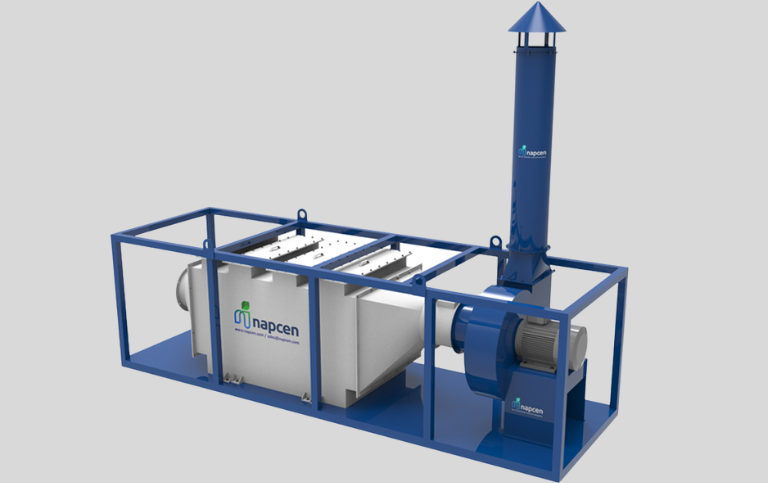

- Modular airflow from 500 m³/h to 20,000 m³/h—ideal for desktop lasers up to large cutting beds

- Laser Cutting, Engraving & Marking Industries

- Electronics & PCB Manufacturing

- Medical Device Manufacturing

- Battery & EV Component Production

- Packaging & Printing Industries