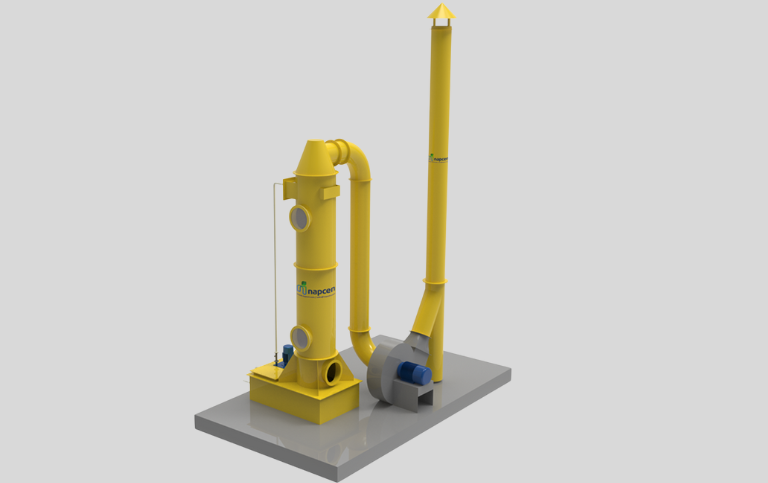

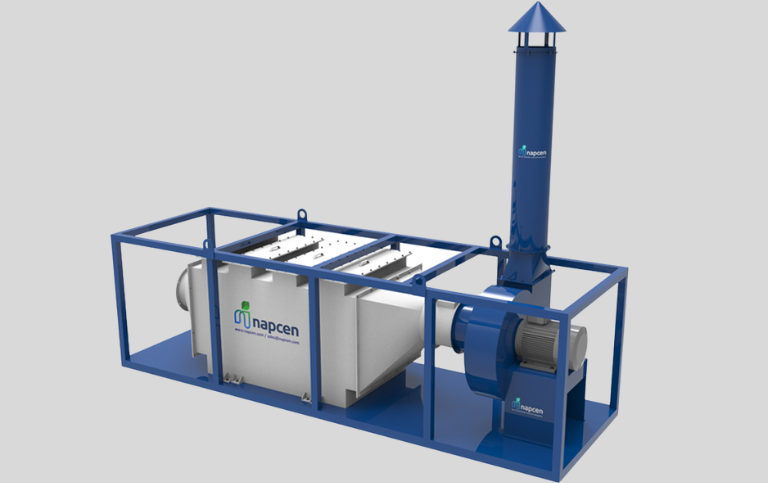

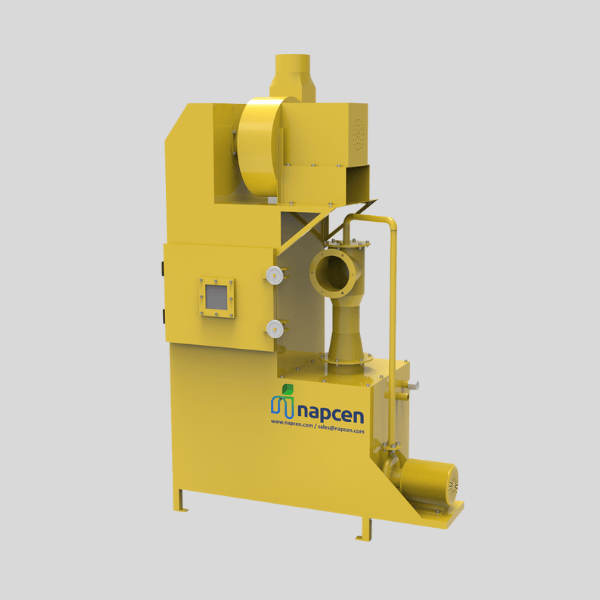

Venturi Scrubber

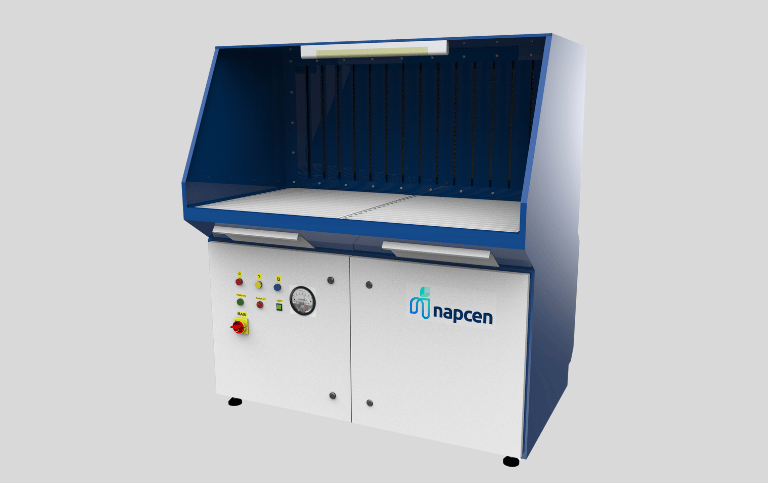

Venturi scrubbers are high-efficiency air pollution control devices that use high energy to atomize liquid into fine droplets, effectively capturing and removing pollutants. By creating intense turbulence and strong interaction between gas and liquid phases, they are especially effective at removing micron and submicron-sized particles. NAPCEN Venturi Scrubbers are specially engineered to handle fine dust, fumes, vapors, mists, and other hazardous pollutants from exhaust gases.

Categories:

Venturi ScrubberVenturi scrubbers use high-velocity gas to create intense turbulence, breaking the scrubbing liquid into fine droplets. This increases the contact surface area, enhancing the capture of fine particulates and absorption of soluble gases. The cleaned gas and droplets are separated downstream using devices like cyclone separators or demisters. These scrubbers are highly effective in removing mists and fine particles, making them ideal for metal processing, chemical plants, and power generation. Their durable design allows operation under high temperatures and gas velocities, ensuring reliable performance.

Why Choose Our Venturi Scrubber?

- Ultra-fine particulate removal down to 0.5 µm

- Adjustable throat design for low pressure drop and energy savings

- Corrosion-resistant PP/FRP or stainless-steel construction

- Modular capacities from 1,000 m³/h to 80,000 m³/h—ideal for new builds

- Fully integrated pump skid, recirculation tank and mist eliminator for turnkey installation

- Non-ferrous metal melting and foundry operations

- Pharmaceutical API tablet manufacturing

- Chemical fertilizer and acid pickling lines

- Food processing dryers and spray towers

- Biomass solid-fuel boiler exhaust treatment