Welding Fume Extractor

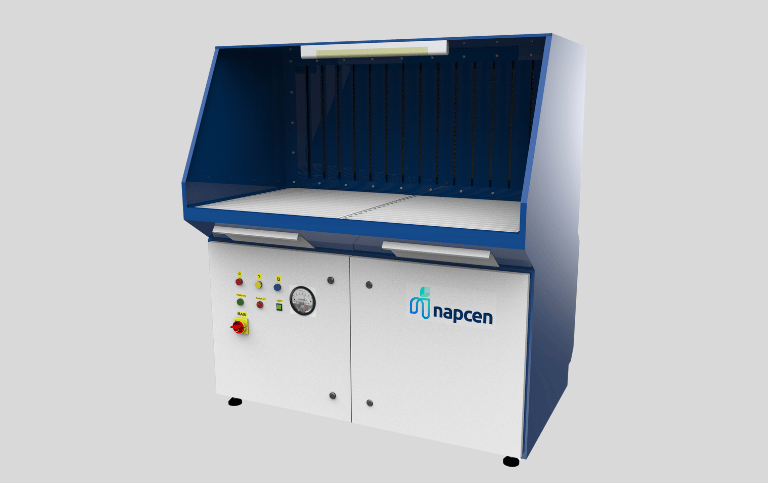

Welding Fume Extractors are essential air filtration systems designed to capture and remove hazardous fumes, gases, and airborne particles generated during welding processes. It allows lightweight and movable components to be worked on directly at the bench. The table is equipped with an integrated downdraft ventilation system that pulls fumes and dust downward through the perforated surface, preventing harmful particles from dispersing into the air.

Categories:

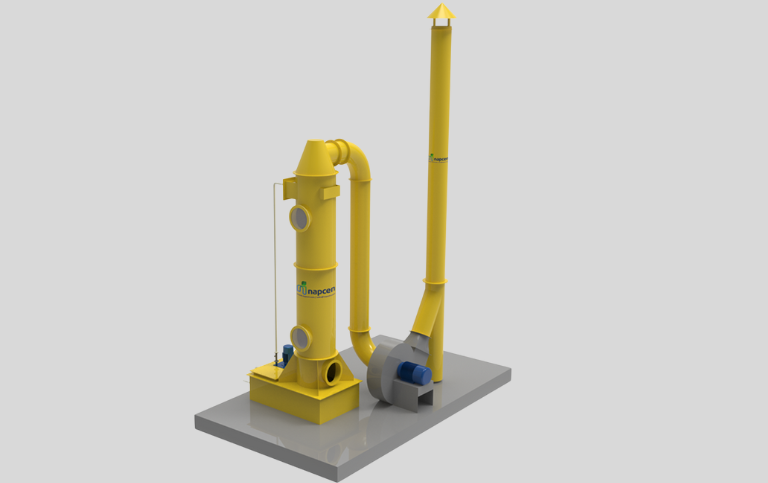

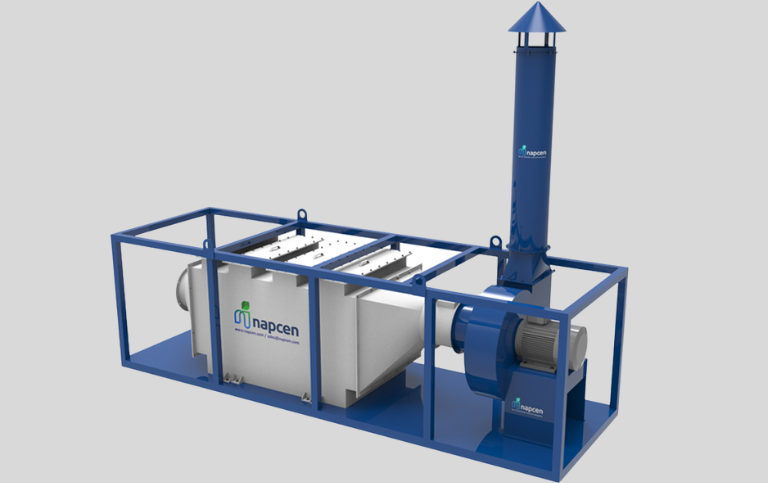

Welding Fume ExtractorsNapcen welding fume extractors are engineered to effectively extract these contaminants at the source, using flexible suction arms, downdraft tables, integrated extraction hoods. The extracted air is passed through multi-stage filtration systems, typically including pre-filters, cartridge filters, and activated carbon filters, ensuring efficient removal of fine particles and gases. Compact and highly efficient, Napcen’s units are suitable for various welding processes including MIG, TIG, and arc welding.

Why Choose Our welding fume extractors?

- 99.9% efficiency in capturing toxic welding smoke and fine particulates

- Multi-stage filtration: Pre-filter, HEPA, and activated carbon

- Compact models for table-top, ducted, and robotic welding setups

- Ideal for MIG, TIG, stick welding, and plasma cutting

- Low-maintenance design with optional auto-cleaning system

- Metal Fabrication Steel Manufacturing

- Automotive Auto Components Industry

- Heavy Engineering Equipment Manufacturing

- Foundries Forging Units

- Chemical Electroplating Industries