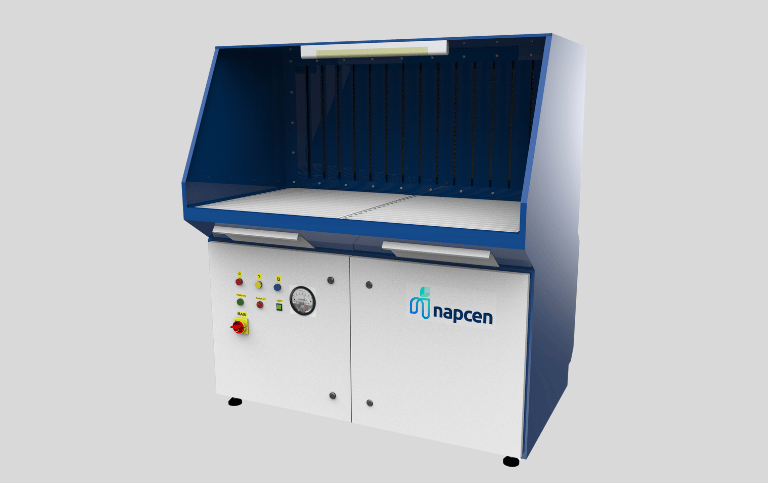

Welding Downdraft Table

Welding Downdraft Table is a specialized workstation designed to capture and filter fumes, smoke, and airborne particles generated during welding, grinding, or cutting operations. It features a built in ventilation system that pulls contaminants downward through the table surface and away from the operator’s breathing zone, improving air quality and ensuring a safer working environment. Ideal for industrial and fabrication settings, downdraft tables often include spark arrestors, filters, and dust collectors to meet regulatory standards.

Categories:

Welding Downdraft TableWhy Choose Our Welding Downdraft Table?

- 99 % fume capture at the welder’s breathing zone

- Integrated spark-trap and disposable pre-filters for fire safety

- Low pressure-drop design reduces fan horsepower and operating costs

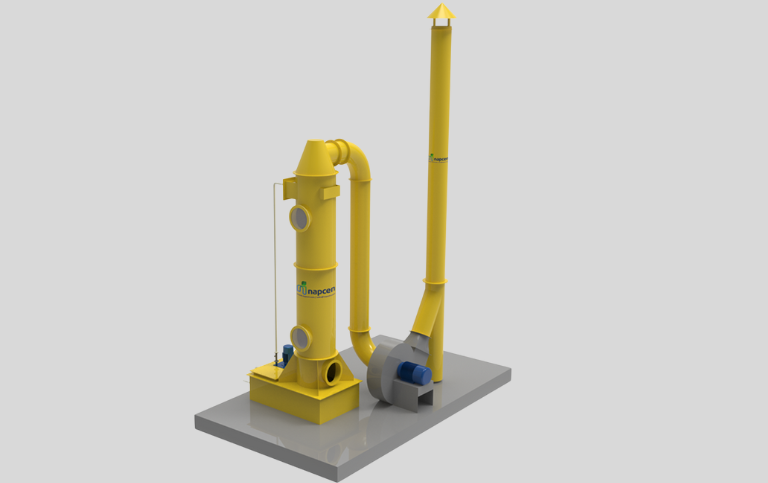

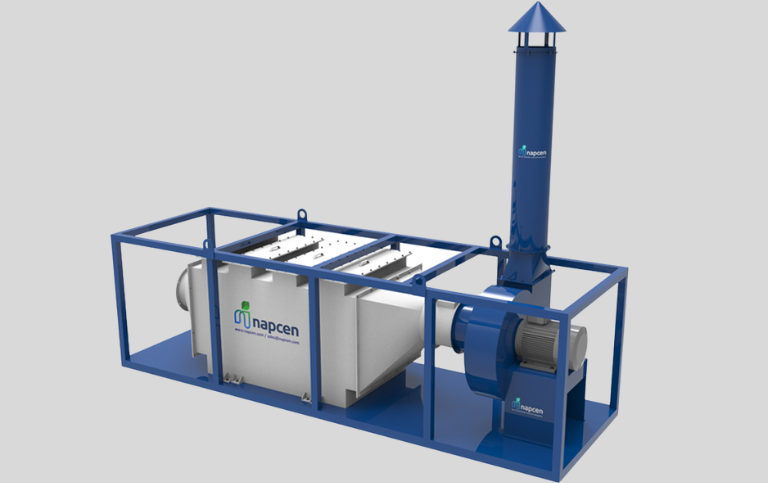

- Corrosion-resistant FRP/PP scrubber body ensures long service life

- Modular airflow from 1,000 m³/h to 30,000 m³/h—ideal for single stations or full production lines

- Metal Fabrication Welding Workshops

- Chemical Processing Plants

- Pharmaceutical Facilities

- Paint, Coating Surface Treatment Units

- Effluent Treatment Plants

Typical Industries Served:

About Effective Fume Control for Safer Welding Operations

Napcen downdraft and backdraft workbench is engineered to effectively capture dust and fumes generated during medium to heavy-duty applications such as grinding, welding, and plasma cutting. This versatile workstation features a powerful downdraft and backdraft extraction system that draws airborne particles through the work surface and back panel, minimizing worker exposure. The downdraft grinding table is especially efficient in removing fine dust and fumes at the source.