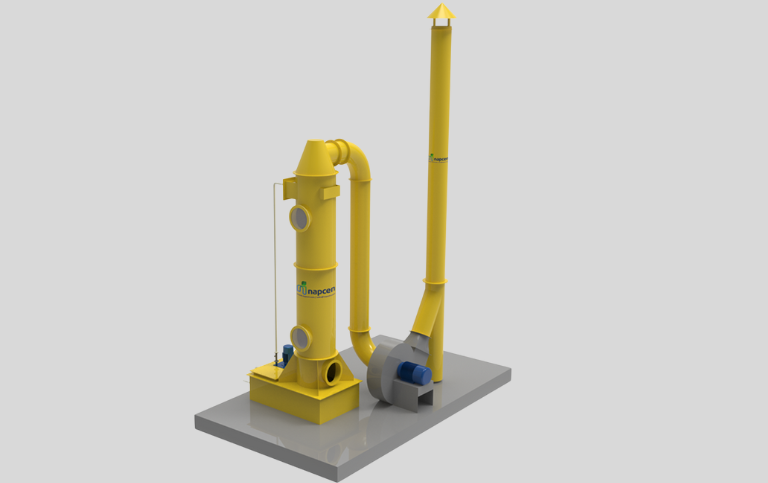

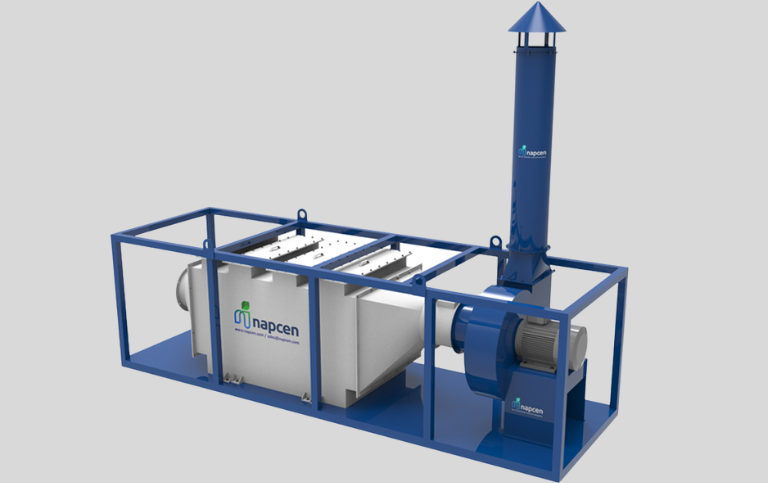

Chlorine Scrubbers

A Chlorine Scrubber is an air pollution control device specifically designed to remove chlorine gas (Cl2) from industrial exhaust streams. Chlorine is a highly toxic, corrosive gas commonly used in water treatment, chemical manufacturing, and pharmaceutical industries. The scrubber works by passing contaminated air through a packed bed or spray tower where it contacts a neutralizing scrubbing solution, typically containing sodium hydroxide. This chemical reaction converts chlorine gas into a harmless salt solution, effectively reducing hazardous emissions.

Categories:

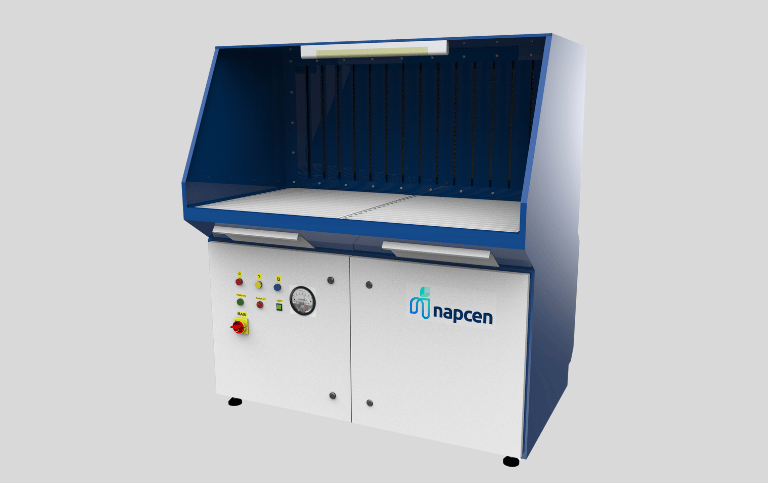

Chlorine ScrubberChlorine scrubbers are engineered to maximize contact between contaminated gas and scrubbing liquid, significantly improving absorption efficiency. Many systems include mist eliminators or demisters to capture residual droplets before the cleaned air is discharged. These scrubbers are crucial for industries that handle or produce chlorine, offering safe and efficient removal of this gas from exhaust streams. By neutralizing chlorine into safer by products, these systems protect worker health, reduce environmental.

Why Choose Our Chlorine Scrubber?

- 99 % removal efficiency for chlorine and acid gases

- Rugged FRP construction withstands harsh chemical environments

- Compact skid-mounted design simplifies installation

- Low pressure drop for reduced power consumption

- Available in capacities from 500 m³/h to 40,000 m³/h

- Chlorine-alkali chemical processing

- Pharmaceutical manufacturing

- Pulp paper bleaching lines

- Water wastewater treatment plants

- Research laboratories and pilot plants