Plasma Cutting Fume Extractor

Plasma cutting is a highly efficient industrial process that uses ionized gas at extremely high temperatures to cut through metal with speed and precision. While effective, this method generates hazardous fumes and smoke containing toxic metals and gases, posing serious health risks to workers if not properly controlled. To ensure a safe working environment, it is crucial to implement effective ventilation and fume extraction systems in plasma cutting areas.

Categories:

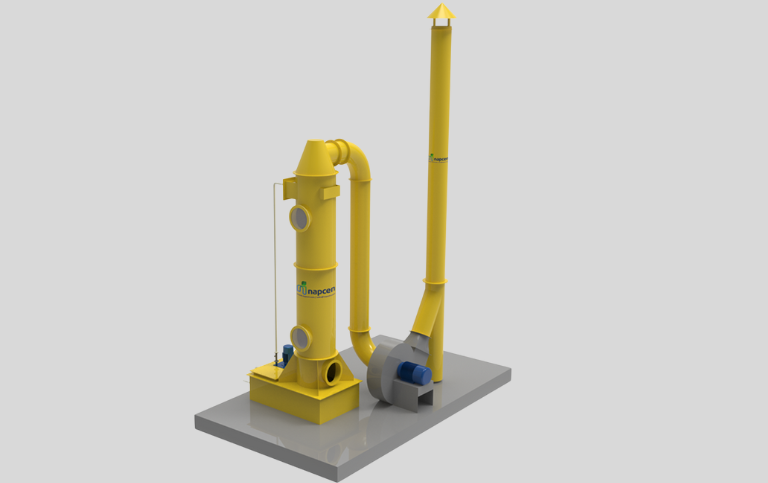

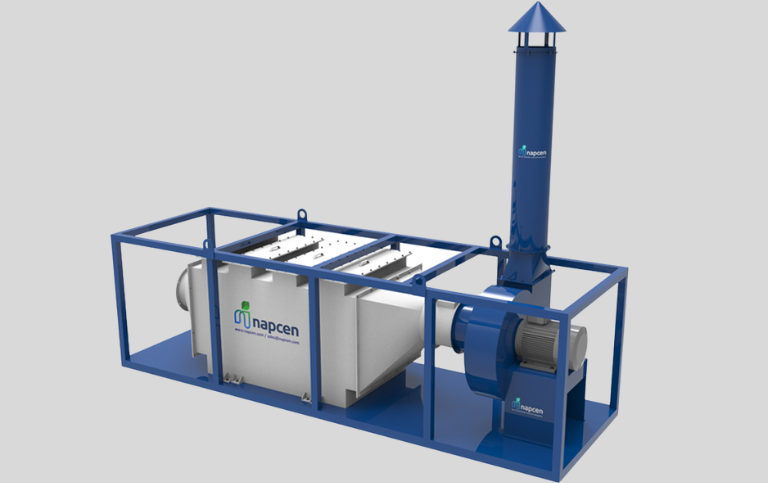

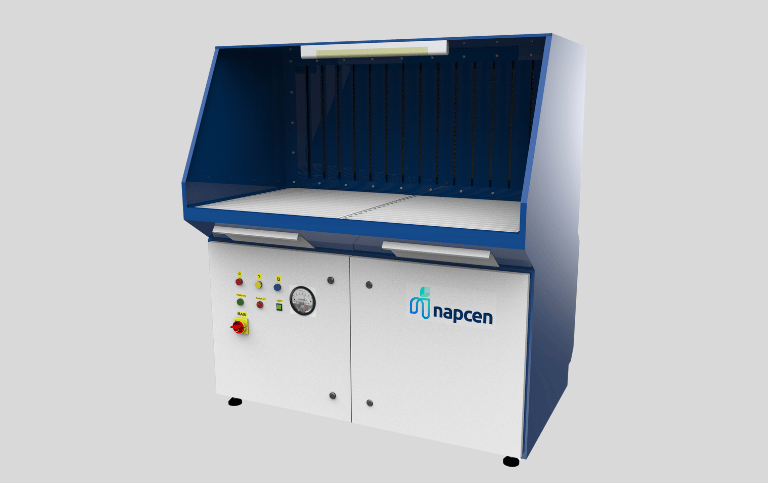

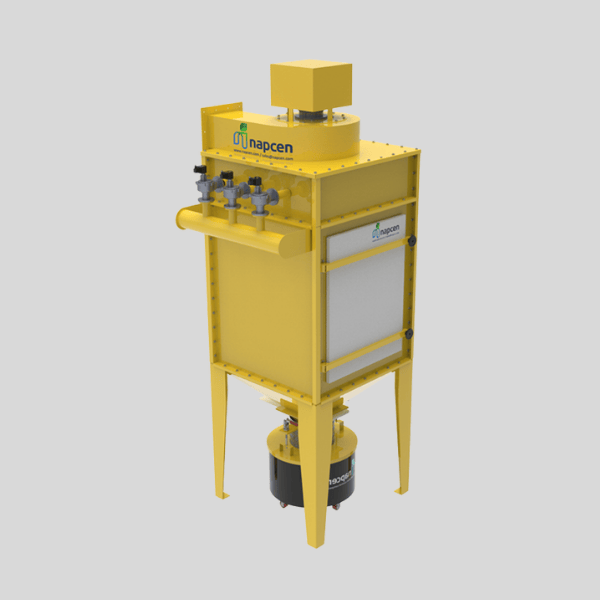

Plasma cutting fume extractorNapcen’s plasma cutting fume extractors use high-efficiency filtration systems typically a combination of pre filters, fine filters, and cartridge filters to effectively remove these contaminants from the air. Suitable for both manual and automated plasma cutting operations, these fume extractors protect employee health while supporting regulatory air quality standards.

Why Choose Our Plasma cutting fume extractor?

- 99.9% filtration efficiency for metallic fumes and fine particulates

- Compatible with CNC plasma, oxy-fuel, and laser cutting tables

- Plug-and-play design with automatic filter cleaning

- Custom-built airflows from 1,000 m³/h to 50,000 m³/h

- CPCB and OSHA compliant performance for clean indoor air

- Metal Fabrication & Steel Processing

- Shipbuilding & Heavy Engineering

- Automotive Parts Manufacturing

- Aerospace & Defense Production

- Construction Equipment & Machinery Manufacturing